What is Corrugated?

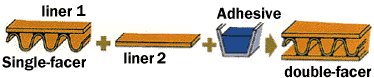

Corrugated board is made from a combination of two sheets of paper called «liners» glued to a corrugated inner medium called fluting.

These three layers of paper are assembled in a way which gives the overall structure a better strength than that of each distinct layer. This ingenious construction forms a series of connected arches which are well known for their ability to support strong weights. This structure gives corrugated board considerable rigidity and resistance. The air circulating in the flutes also serves as an insulator which provides excellent protection against temperature variations. There are many types of corrugated, each with different flute sizes and profiles which offer many combinations designed to create packaging with different characteristics and performances

These three layers of paper are assembled in a way which gives the overall structure a better strength than that of each distinct layer. This ingenious construction forms a series of connected arches which are well known for their ability to support strong weights. This structure gives corrugated board considerable rigidity and resistance. The air circulating in the flutes also serves as an insulator which provides excellent protection against temperature variations. There are many types of corrugated, each with different flute sizes and profiles which offer many combinations designed to create packaging with different characteristics and performances

The corrugated board is then cut and folded into an infinite variety of shape and sizes to become corrugated packaging. Corrugated is a high performance packaging material designed to pack, protect and promote products. Corrugated board is a combination of at least three sheets of paper, collectively called containerboard. The paper layers on the outside are known as the liners, or linerboard, while the fluted or wave-shaped material in the middle layer is called corrugating medium.

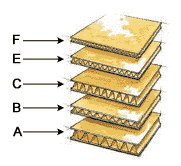

Corrugated board comes in different thicknesses, depending on the height of the flutes, and number of flutes per foot. In industry terms, the three-layer corrugated material shown here is called singlewall corrugated board. Two or three layers of corrugated board can also be combined for stronger packaging requirements. These are called doublewall or triplewall corrugated.It is made of paper and has an arched layer, called "fluting," between smooth sheets, called "liner." The corrugated most commonly used to make boxes has one layer of fluting between two smooth sheets. But there are many types of corrugated available, each with different flute sizes and thicknesses.

Corrugated board comes in different thicknesses, depending on the height of the flutes, and number of flutes per foot. In industry terms, the three-layer corrugated material shown here is called singlewall corrugated board. Two or three layers of corrugated board can also be combined for stronger packaging requirements. These are called doublewall or triplewall corrugated.It is made of paper and has an arched layer, called "fluting," between smooth sheets, called "liner." The corrugated most commonly used to make boxes has one layer of fluting between two smooth sheets. But there are many types of corrugated available, each with different flute sizes and thicknesses.

Flutes come in several standard shapes or flute profiles (A, B, C, E, F, etc.). A-flute was the first to be developed and is the largest common flute profile. B-flute was next and is much smaller. C-flute followed and is between A and B in size. E-flute is smaller than B and F-flute is smaller yet.

Why Corrugated

Corrugated is an extremely durable, versatile, innovative and lightweight material used for custom-manufactured shipping containers, packaging and point-of-purchase displays, in addition to numerous non-traditional applications ranging from pallets to children's toys to furniture.

These boxes provide some measure of product protection by themselves and also the corrugations help enhance various properties of the board including

This is the reason that corrugated boxes are prefered over normal cardboard boxes.

One of the important functions of a corrugated box is to provide crush resistance (product protection) and adequate strength for stacking in warehouses.

A box can be designed by optimizing the grade of corrugated board, box design, flute direction, and inner supports. Support from the product also provides "load sharing" and can be an important factor. Box closures sometimes can have effects on box stacking strength.

If long-term storage of corrugated boxes in high humidity is expected, extra strength and moisture resistance is called for.The method of loading boxes on pallets strongly affects stacking. Vertical columns provide the best box performance while interlocking patterns of boxes significantly reduce performance. The interaction of the boxes and pallets is also important.